Related

How Groyyo Uses AI to Improve Manufacturing Efficiency

Discover how Groyyo leverages AI to enhance manufacturing efficiency, reduce errors, and streamline operations for factories.

Popular topics

02 min reading in—ManufacturingAutomation

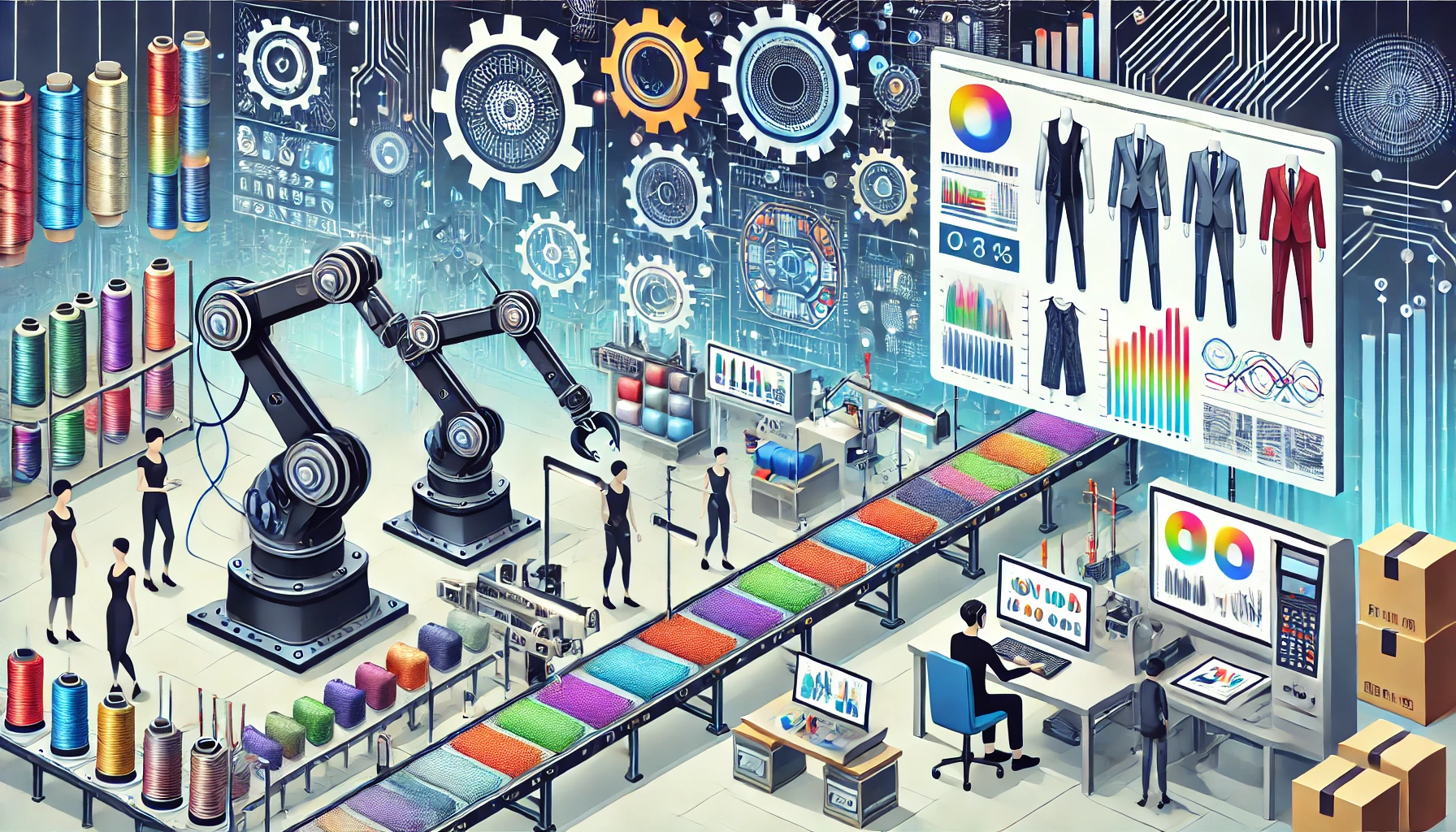

Explore how Groyyo’s automation tools streamline manufacturing processes, reduce errors, and enhance productivity in factories.

Efficiency is key to success in manufacturing, and automation plays a critical role in achieving it. Groyyo provides cutting-edge automation tools that enable factories to streamline their processes, reduce human errors, and boost productivity. These tools help manufacturers operate more efficiently and meet the increasing demands of the market.

Automation allows factories to handle repetitive and time-consuming tasks with greater precision and speed. By automating workflows, manufacturers can reduce manual labor, minimize errors, and free up their workforce for higher-value activities. This leads to improved productivity, consistent product quality, and lower operational costs.

Automated Workflow Management: Groyyo’s tools help factories automate various stages of production, from scheduling and material handling to quality checks. This ensures that production runs smoothly and reduces the chances of delays.

Real-Time Monitoring and Alerts: Groyyo’s automation systems come equipped with real-time monitoring features that alert managers to any irregularities or potential issues. This proactive approach helps prevent production stoppages and reduces downtime.

Integrated Systems: Groyyo’s automation tools integrate seamlessly with existing factory management systems, allowing for smooth data flow and comprehensive oversight. This ensures that all parts of the production line are working in harmony, contributing to overall efficiency.

Error Reduction: By automating repetitive tasks, Groyyo helps reduce the risk of human error, which can lead to costly rework and delays. Consistency in automated processes ensures high-quality production with fewer interruptions.

Factories that adopt Groyyo’s automation tools experience faster production cycles, improved resource allocation, and a significant reduction in manual errors. This leads to higher productivity, consistent product quality, and greater operational efficiency.

Automation is a powerful asset for modern manufacturers, enabling them to stay competitive and meet the demands of a fast-paced industry. Groyyo’s automation tools provide factories with the technology needed to optimize their operations, reduce errors, and enhance productivity. For factories aiming to operate more efficiently and sustainably, Groyyo’s solutions are the key to unlocking greater success.

Related

Discover how Groyyo leverages AI to enhance manufacturing efficiency, reduce errors, and streamline operations for factories.

Related

Learn how Groyyo helps factories tap into global markets and expand export opportunities through strategic partnerships and technology-driven...

Related

Learn how Groyyo assists factories in transitioning to digital processes, enhancing productivity, transparency, and operational efficiency through...